Case Studies

HOTLEY BOTTOM

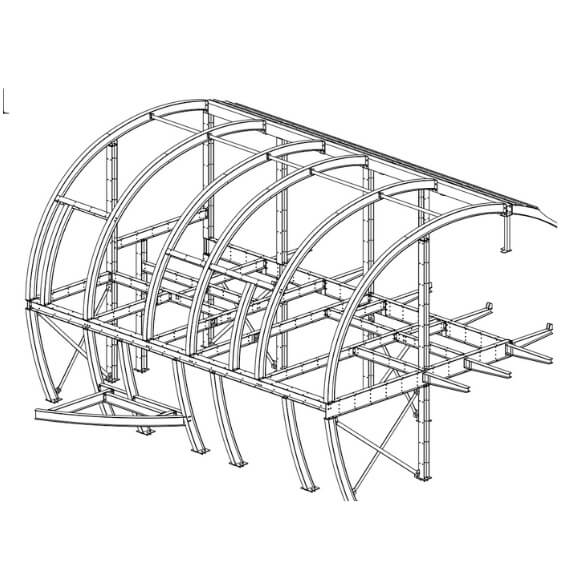

The ten-and-a-half-tonne residential project was an incredible test for our team.

Many factors lead to this being a highlight project for Steelo including six dual-radius curved beams, the longest of which was nine meters in length. We worked closely with Vision Developments South Ltd. to make sure the client’s needs were met. We also liaised with Splendid Effect Ltd.

The steel erection team selected for this project, to make sure they were on-site and ready to build the structure as soon as the steel was on site.

“Steelo Ltd recently completed a project at Hockleys Well Street, Burghclere, RG20 9NH. We have worked closely with Steelo on this project, and I am pleased to share our positive experience with their team Throughout the project, Steelo Ltd demonstrated a high level of professionalism, expertise, and commitment. Their work on the structural elements was particularly impressive, with all tasks completed to an exceptionally high standard and within the agreed timeframe. Their attention to detail and ability to meet our specific requirements ensured that the project ran smoothly and efficiently from start to finish. Communication with Steelo Ltd was clear and consistent, and any challenges that arose were handled promptly and effectively. Their team was always responsive and willing to go the extra mile to ensure our satisfaction. I would not hesitate to recommend Steel Ltd for similar projects and would be happy to work with them again in the future”

L. M – Contracts Manager

Vision Development South LTD

KENSINGTON ROOF GARDENS

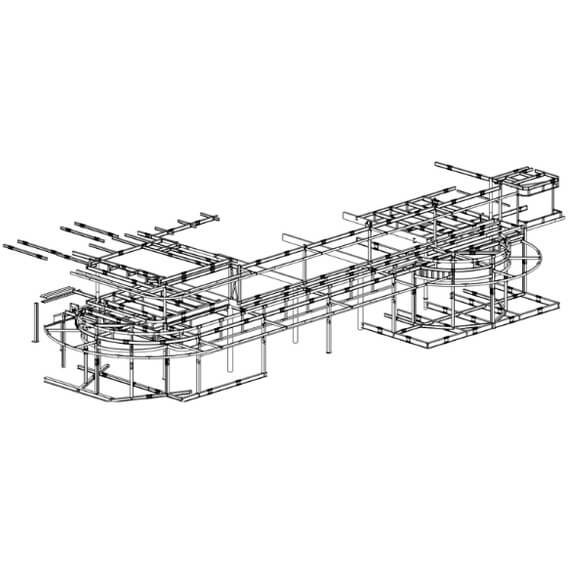

For this project, we delivered 60 tonnes of structural steel fabrication for Arcacia Limited at the Kensington Roof Gardens. The complex steel framework,was meticulously designed and fabricated for a major construction endeavor.

This structure highlights Steel’s expertise in managing intricate designs, incorporating challenging elements such as dual-radius curved beams and numerous connection points that demanded careful planning and precise execution.

“We have worked with Steelo for many years on both large and small projects. They have always been excellent to deal with both in terms of design coordination but also the efficiency and speed at which the steel is delivered to us. The projects have varied in complexity. The Roof Gardens was by far the most complicated thus far in terms of both engineering but also logistics and split deliveries. Steelo dealt with all of this superbly. It is fair to say that Arcacia have never needed to look tor another supplier”

Emma Fyffe

Project CoOrdinator

Arcacia Consulting Ltd

THE LANE

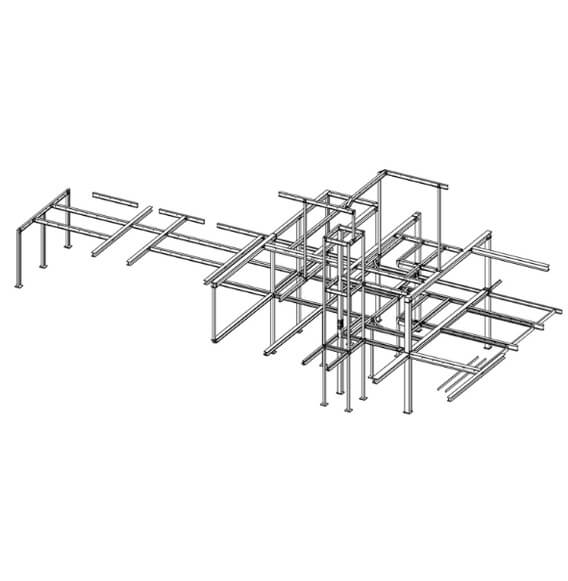

The nearly 30-tonne steel project was a challenging and exciting undertaking for our team. The structure consisted entirely of straight beams, including various sizes with weights ranging from 259 kg to 2803 kg and lengths up to 19.15 meters.

This project posed a unique challenge for the contractor due to the requirement to maintain the existing façade of the building located close to Abbey Road Studios.

“I can confidently say that Steel are one of the best fabricators on the market. We’ve worked with Steelo on numerous projects and they have always delivered exceptional results. Most recently, they were instrumental in completing vet another successful project, providina precise structural steel fabrications that were of the highest qualitv

Their ability to deliver on time, has been crucial in helping us maintain our project schedules. The prompt delivery of materials to site allows us to plan and execute our projects smoothly and without any delays. Steel’s attention to detail and precision in fabrication always ensures that all components fit perfectly, which reduces our installation time and helps to keep everything on track.

1 highly recommend Steelo to anyone in need of a trustworthy and dependable steel fabricator”

Gregory Horodenski

Smart Conversion Ltd

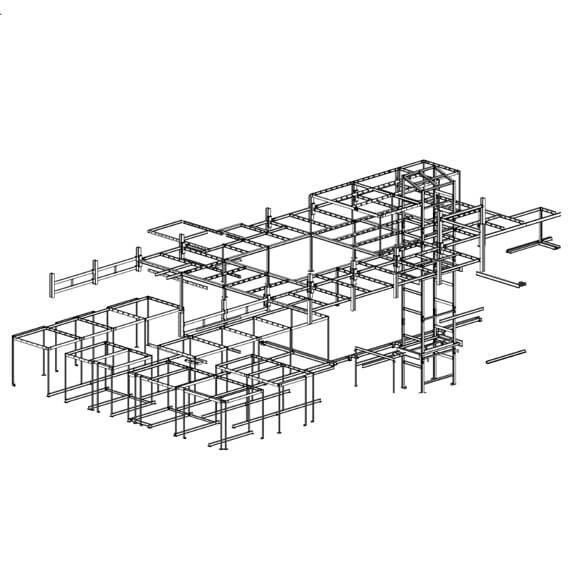

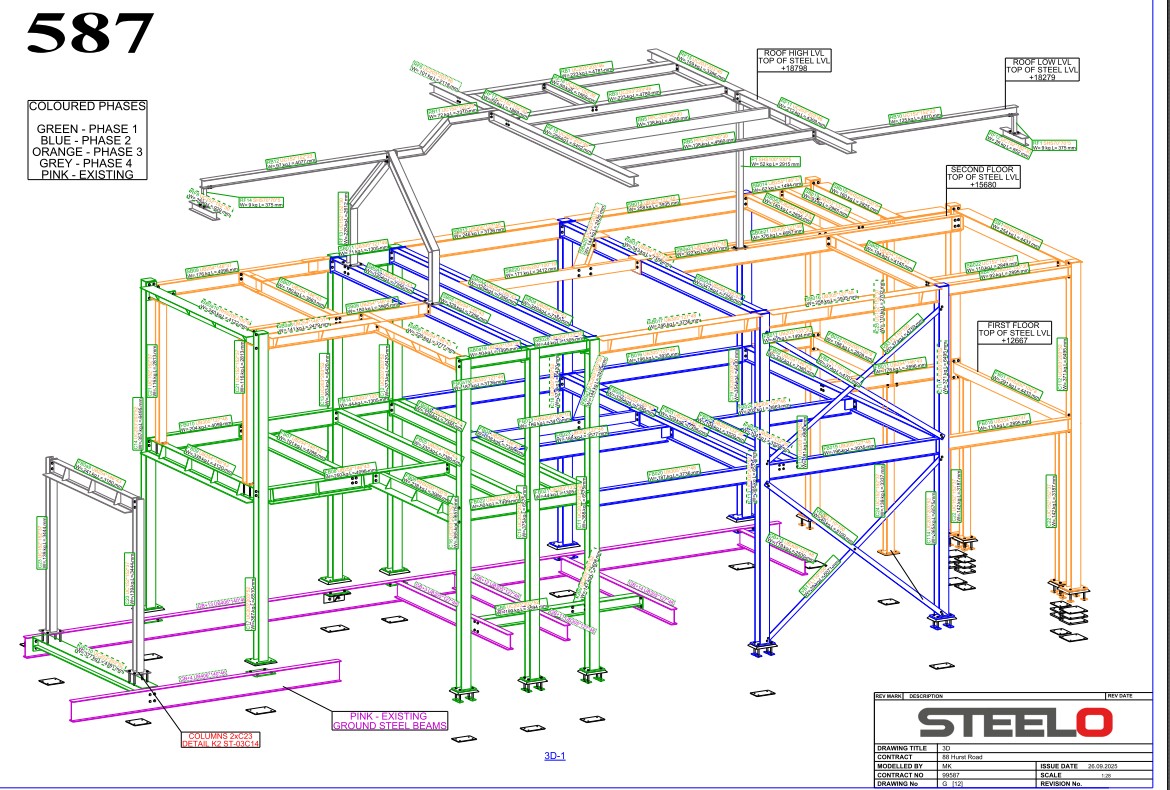

BBC - EARLSTREE

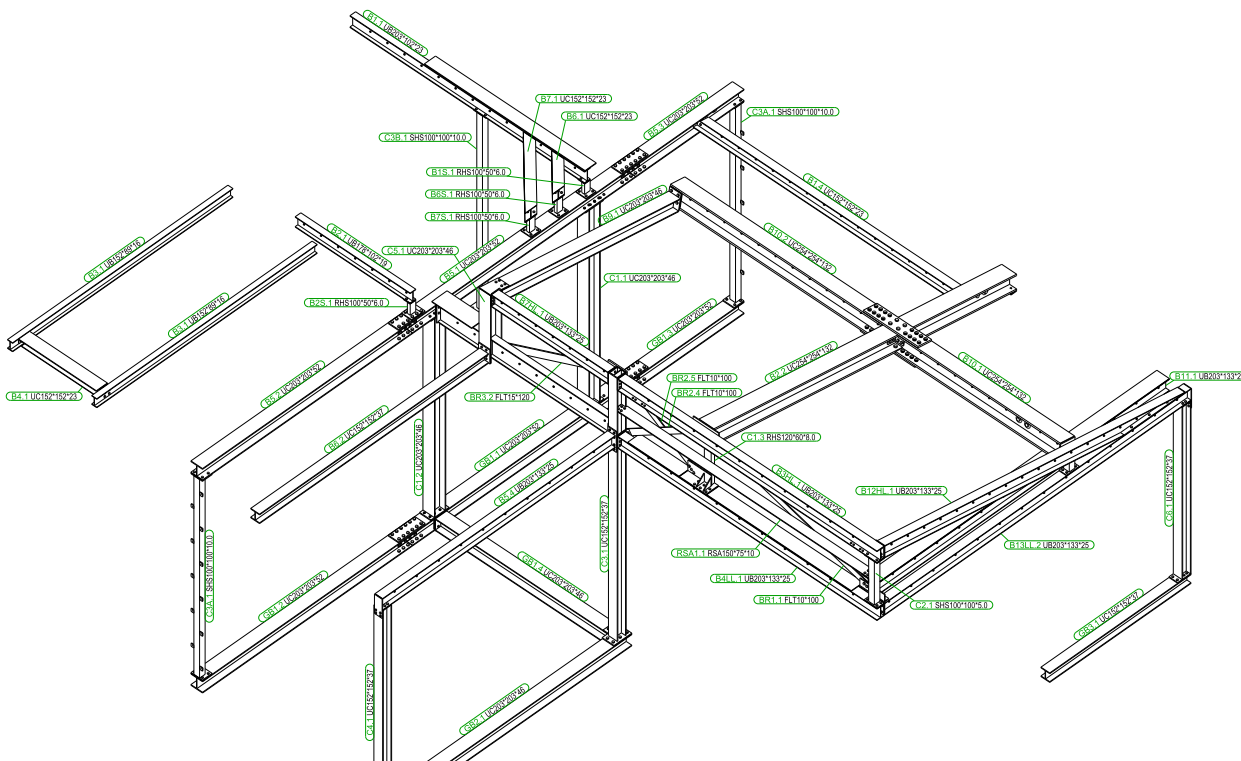

This nearly 50-tonne steel project posed a considerable challenge for our team, requiring fabrication in stages and erection by our mobile welding team. The structure comprised a variety of steel sections, including SHS, UC, UB, PFC, and RHS beams, with the heaviest component weighing 7,849 kg and measuring over 335 meters in length. This project involved fabricating steel structures that allowed the client to create mezzanine floors within a film studio. The aim was to divide a single floor into two usable levels, as the ceiling height was sufficient to accommodate the additional space. We worked closely with Henny Ltd. to ensure that the client’s requirements were fully met.

To streamline the process, our in-house systems ensured the steel fabrication was carried out with precision and within the necessary tolerances.

EAST DULWICH GROVE

For this project, Steelo was entrusted with the fabrication and delivery of structural steel to support a highly specialized load-bearing extension. Unlike standard builds, this extension required additional structural reinforcement to accommodate photovoltaic panels, creating a need for increased load capacity while maintaining an open-plan design.

One of the most unique aspects of this project was the architectural vision for an open space, which meant that several beams appeared to be floating in the air. This effect was made possible through expertly detailed steel connections, designed to distribute the load efficiently while maintaining structural integrity.

The fabrication involved a combination of Universal Columns (UC), Universal Beams (UB), and Square Hollow Sections (SHS), with some of the heaviest beams exceeding 9.7 meters in length and weighing over 500 kg each. The steelwork had to be precisely cut, drilled, and primed, ensuring that each section was ready for seamless installation.

Thanks to the innovative engineering connections, the extension was able to achieve a visually striking effect, where some of the beams seemed to “float” due to the hidden support mechanisms and strategic load distribution. The use of RHS and SHS sections, along with custom base and end plates, allowed for the required strength without compromising the aesthetics of the open-plan design.

A big thank you to @make.structures (Structural Engineer), @simonwhiteheadarchitects (Architect), and @new_smart_living_designbuild (Contractor) for their incredible work on this project!

ULLSWATER ROAD

The Ullswater Road project required a high level of expertise in steel fabrication and installation. The objective was to enhance the structural capacity of an existing property by integrating custom steel components to support mezzanine floors and a rear extension. This transformation was essential to maximizing available space while maintaining the architectural integrity of the building.

Working alongside Three Oaks Bespoke Ltd., our team developed a customized steel solution that met the highest standards in structural design, material selection, and installation. The complexity of the project was comparable to assembling an intricate puzzle, where each piece had to fit precisely to support the load-bearing framework.

The scope of work included the fabrication of custom steel elements, including SHS, UC, UB, PFC, and RHS beams. The project also required the installation of primary and secondary support structures for the mezzanine floors, as well as the provision of steel reinforcements for the rear extension. Ensuring compliance with CDM regulations and strict health and safety protocols was a key priority throughout the project.

A combination of heavy-duty steel sections was used, with the largest individual component weighing 7,849 kg and spanning over 335 meters in length. Each steel piece was meticulously fabricated, primed, and installed with precision to ensure the durability and longevity of the structure. The steel components included Universal Columns (UC 152 x 37), Universal Beams (UB 457 x 152), Square Hollow Sections (SHS 100 x 100 x 5), Parallel Flange Channels (PFC), and Rectangular Hollow Sections (RHS). Each element played a critical role in distributing loads and reinforcing the building envelope.

Executing this project required seamless coordination between fabrication, transportation, and on-site assembly. The mobile welding team ensured that all connections were secure and within tolerance, working in close collaboration with engineers to ensure efficiency and accuracy in execution.

FAIRWAY

At Fairway, Carshalton SM5, Steelo was entrusted with the fabrication and delivery of 2,500 kg of structural steel, including a 9-meter-long beam weighing 1,800 kg. Precision and efficiency were at the core of our process, ensuring that all components were fabricated to the highest standards and delivered on time.

One of the biggest challenges of this project was the sheer size and weight of the beams, which made site logistics particularly complex. The structural engineer rejected a splice for the heaviest beam, requiring it to be transported in a single piece. This restriction meant that the beam could not be lifted over the house and had to be maneuvered through a tight access route to reach the rear of the property, where the extension was planned.

Steelo’s expertise ensured that every steel section was manufactured to exact specifications and prepared for installation. With our efficient production process and streamlined logistics, we delivered the steel promptly, providing the structural elements needed to keep the project moving forward.

While the challenge of moving the beams on-site required significant effort, our role in delivering high-quality, precision-fabricated steel ensured that the project remained on track. This case highlights the importance of carefully planned fabrication and reliable delivery, both of which are at the heart of Steelo’s service.

Delivery on time, driver very helpful like always.

Good service, we’ve been working together 8 years 🙂

Chris – New Comfort Ltd.

WALWORTH DEPOT, SOUTH LONDON

As London accelerates towards a zero-emissions future, Steelo was proud to play a key role in delivering the structural framework supporting Abellio London’s latest electric bus charging infrastructure. Tasked with fabricating and installing a bespoke gantry system, Steelo helped enable overnight charging at Abellio’s Walworth depot—supporting Transport for London’s (TfL) 2035 target for a fully electric bus fleet.

Abellio required a space-efficient, high-capacity solution to support the charging of 34 new electric buses operating on routes C10 and P5. With limited space, restricted grid capacity, and a 24/7 operational environment, the project demanded meticulous planning and precise execution.

Steelo engineered and fabricated a custom steel gantry designed to support multiple DC fast chargers, each capable of delivering over 80kW. The gantry’s structure had to be both robust and adaptable, accommodating retractable charging heads to maximize operational flexibility.

Installation involved lifting 12-meter beams to a height of six metres, requiring external transport and specialist lifting equipment, including a spider crane. A temporary support frame was also devised to stabilize existing infrastructure throughout the process.

Despite the challenges, Steelo delivered the project on schedule and to spec—ensuring Abellio’s electric fleet could begin charging immediately. The gantry not only provides a structural backbone for charging equipment but also integrates seamlessly into a live depot environment without disrupting daily bus operations.

“We had just five days to complete the installation with only three parking bays available for storage,” said Kate Ustianowska, Technical Estimator at Steelo. “Every day, we had to completely demobilize, then remobilize our kit the next morning. It was a tight turnaround under complex conditions.”

“This was one of the most interesting and rewarding projects I’ve worked on,” added Kate. “It pushed us to collaborate across disciplines and adapt quickly, which is exactly what Steelo thrives on.”

BASINGSTOKE, HAMPSHIRE

This project demonstrates the power of hybrid construction in delivering a high-performance new-build home in rural Hampshire. Vision Development, a specialist in timber frame construction, led the project to demolish an outdated three-bedroom bungalow and replace it with a newly built 1.5-storey, four-bedroom detached house designed to meet modern efficiency and design standards.

Steelo was brought in to fabricate and supply the structural steelwork essential for the build. Over 3.25 tonnes (3,250 kg) of primed steel were delivered to site, including precision-cut UB, UC, and SHS sections with custom end and base plates. Each element was engineered to integrate seamlessly with the timber frame system, providing support at critical load points such as ridge lines, openings, and floor structures.

The combination of timber and steel allowed the project team to maximize design flexibility, enabling wide, open-plan interior spaces and complex architectural details that timber alone could not support. The steelwork played a key role in reinforcing the timber frame without compromising the project’s sustainability and speed of construction goals.

Our scope involved the fabrication and timely delivery of all structural steel elements required for the new home, ensuring minimal disruption to Vision Development’s construction schedule. The design also met airtightness and energy performance expectations, aligning with the build’s low-impact and future-ready objectives.

Timber frame was chosen for its rapid assembly, thermal efficiency, and reduced environmental footprint, while structural steel provided the additional strength and support needed for long spans and open layouts. Together, these materials formed a resilient, efficient, and architecturally striking new dwelling—purpose-built for modern living.

.

Thinking of a self-build? Estimate your timber frame project here:

Self-Build Cost Calculator

Learn more about timber frame advantages:

https://www.timber-frame-suppliers.co.uk/timber-frame-benefits/

CHISWICK BUSINESS PARK

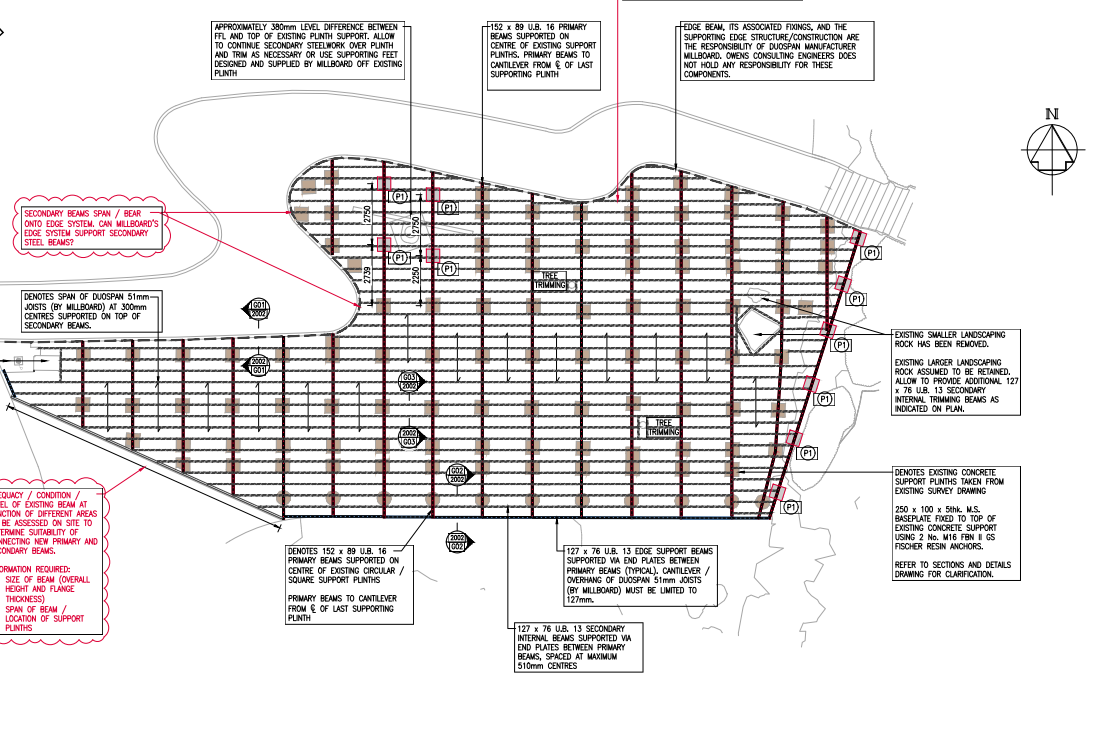

At Chiswick Business Park, Steelo was engaged to fabricate, supply, and install galvanised structural steelwork to support a new Millboard composite decking system being constructed on-site. The decking was designed to span across a network of existing concrete pads, and our scope involved bridging these spans with precision-engineered steel beams tailored to suit the decking layout.

The supporting frame was primarily constructed from 127 x 76 x 13 UB sections, configured to match specific joist spacings and load paths as defined in the mark-up drawings. In total, we supplied and installed over 15.78 tonnes of galvanised steel, including four principal beams and numerous support members—each fabricated to strict tolerances and installed with exacting care.

A key challenge in this project was navigating the existing site conditions. With variations in plinth heights and pad alignments, installation required meticulous coordination between our on-site team and the project designers. Every component had to be aligned perfectly to support the decking system, with all primary and secondary beams pre-drilled and detailed to integrate seamlessly with the Duospan layout.

Our in-house team handled both the fabrication and on-site installation, logging 76 hours of production and executing the installation without disruption. All elements were galvanised for long-term durability in a high-traffic commercial setting, and installed in accordance with strict QA protocols—ensuring a precise fit from the ground up.

This project reflects Steelo’s end-to-end capability in delivering structural steel solutions for complex commercial environments. While we were not involved in the decking itself, our work formed the structural backbone of the system—designed, delivered, and installed to perform.

We were proud to work alongside Celltarga on this Chiswick Business Park project. Their clear coordination and expert site management helped make our steel installation smooth and efficient.

Check out more of their great work: celltarga.com/our-projects

LEYFIELD, WORCESTER PARK KT4

This project involved transforming an existing three-bedroom semi-detached house with an integral garage into a substantially larger family home with a new two-storey side and rear extension, loft conversion with a rear dormer and Juliet balcony, and multiple rooflights. To achieve this, the entire internal structure was demolished, leaving only the original front façade standing.

Working alongside Klas Projects Ltd — an established building company known for delivering high-end residential refurbishments and extensions — Steelo provided a full supply and installation service for the structural steelwork required for this ambitious rebuild.

Over 8.6 tonnes of structural steel were fabricated and installed in carefully planned phases. We first erected the steel frame for the new ground floor footprint. Once the builders completed the brickwork for the new storey, we returned to install the next level’s structural beams and columns. This staged approach was repeated until the new roof structure was in place, ensuring a safe and efficient build sequence in a tight residential setting.

Klas Projects managed the overall build to their usual high standard — combining quality craftsmanship with meticulous project management. Find out more about their work and services here: Klas Projects.

GRANVILLE ROAD, LONDON

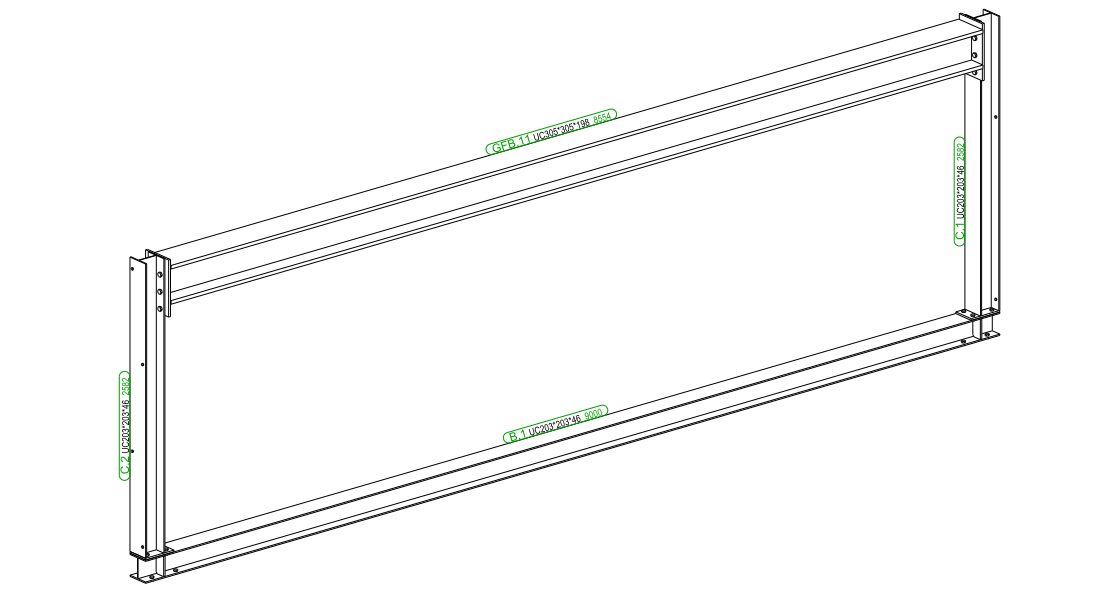

Steelo was commissioned to supply and install the full structural steel package for a major residential redevelopment at Granville Road, SW21. The project required basement, ground, first, and second-floor frameworks, delivered in a staged programme to coordinate with excavation, underpinning, and superstructure works.

Scope of Works

The design incorporated a mix of heavy Universal Columns (UC), Universal Beams (UB), Rectangular Hollow Sections (RHS), and Square Hollow Sections (SHS). Key sections included UC 305×305, UC 254×254, and UB 203×133, providing the primary load-bearing framework across all levels. Steel schedules called for over a dozen beam and column types, including custom padstones and flitch beams to integrate with blockwork and timber joists.

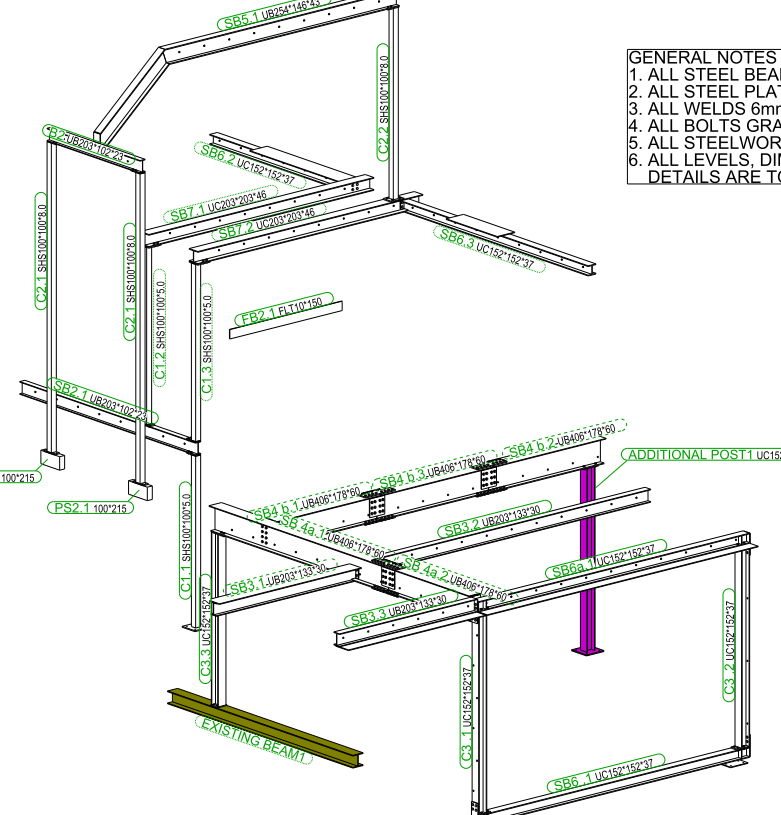

The basement stage involved underpinning and installation of pad foundations (up to 1500x1500x500mm) with UC columns and RC retaining walls. At ground and first floor, the steel package supported ribdeck slabs and load-bearing blockwork, while the upper levels combined timber joists and flitch beams with secondary steel members.

Delivery & Installation

Due to access constraints and sequencing with excavation and concrete works, the steel package was delivered and installed in phases. Temporary bracing was essential throughout installation until stability walls and permanent connections were completed. Mobile cranes and careful coordination with the site team ensured safe lifting of heavy UC and UB members in a constrained residential setting.

Outcome

The staged steel installation provided a robust, integrated framework from basement through to roof level. Precision fabrication and phased delivery enabled smooth progress despite tight site conditions and sequencing challenges. The completed frame ensures long-term stability and supports the architectural intent for this multi-storey development.

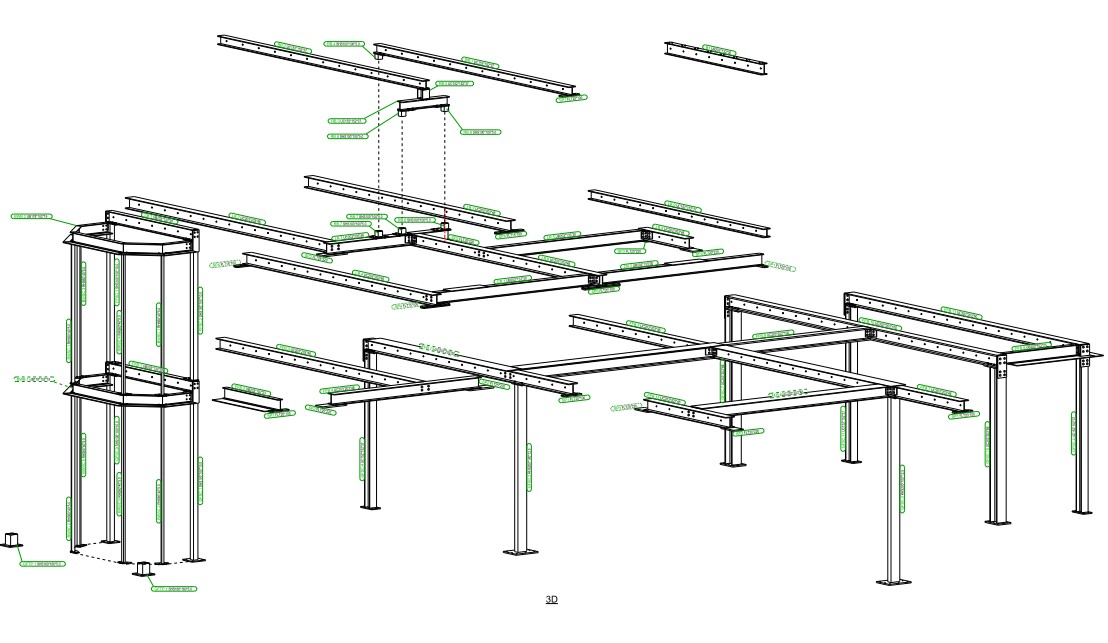

NOTTING HILL, LONDON

This project involved the design, fabrication, and installation of a steel podium structure on the top floor of a semi-detached house in W10. The scheme had faced delays due to design changes and planning approvals, so when Rockgrove approached us, they were eager to move quickly and secure a reliable partner to deliver the steelwork package on a tight programme.

Steelo was commissioned to provide a full-service solution — from survey and design right through to installation. Our team began with an on-site survey and produced detailed fabrication drawings and connection designs for engineer approval. Once signed off, we fabricated a total of thirty beams and 216 individual elements, with a combined weight of 2.87 tonnes. Each piece was cut, drilled, welded, and primed to meet the project specifications and prepared for off-site intumescent painting.

Over 88 hours of fabrication work went into this package, which was then delivered to site by crane in carefully planned phases to work seamlessly with the existing scaffold and loading platform. Our installation team erected the steel frame safely and efficiently, including fixing back to the existing structure and chemfixing the baseplates to the top of the wall, as specified.

The result was a fully installed, primed steel podium frame, ready for the next stage of construction.

Despite the earlier design-related delays, Steelo’s fast response, coordinated delivery, and professional installation enabled Rockgrove to take full advantage of the summer build window and keep the project on track.

EAST MOLESEY, SURREY

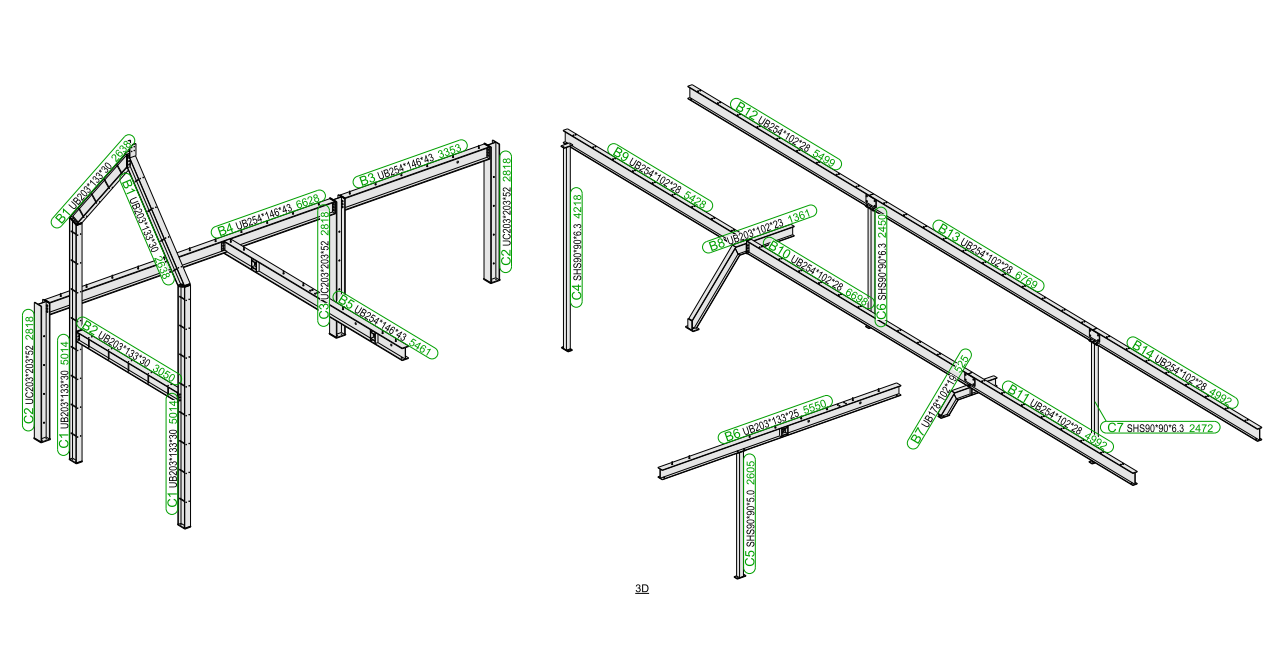

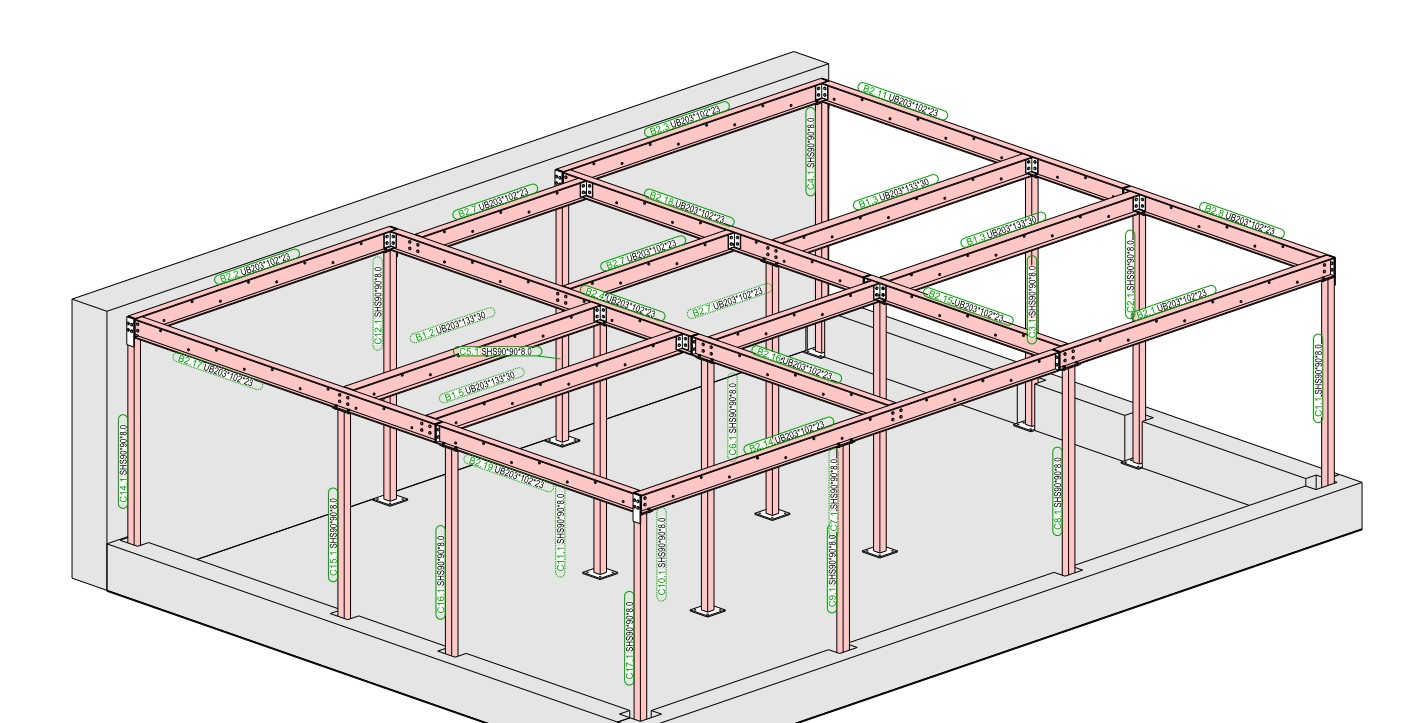

This project involved the fabrication and erection of a two-storey structural steel frame for a new residential development in East Molesey, Surrey. The scheme required a technically detailed and accurately installed steel frame to support the construction of a new high-end property on a restricted site with neighbouring properties in close proximity.

The design included a combination of UC columns, UB beams, PFC sections, and RHS members, along with multiple cleats, end plates, and stiffeners to achieve the complex load paths specified by the structural engineer. All members were fabricated, drilled, welded, and finished with red oxide primer to ensure corrosion protection before being delivered to site.

The project began with a full on-site survey to confirm foundation positions, baseplate levels, and access constraints. Detailed fabrication drawings and connection designs were prepared and submitted for approval to ensure that each component would fit accurately during installation. Once fabrication began, over 390 hours of workshop time were dedicated to the package, which consisted of 113 beams and 449 fabricated elements with a total weight of 22.25 tonnes. Each member was cut, drilled, welded, inspected for dimensional accuracy, and coated with primer before being dispatched for installation.

Delivery and installation were carried out in carefully planned phases. Steelwork was delivered in loads sequenced to match the erection programme, and a mobile crane was used to position the larger members safely and efficiently. The frame was erected in a logical sequence, beginning with the columns and primary beams, followed by the secondary members, bracing, and connection details. Baseplates were levelled and fixed, and all connections were bolted and torque-checked to meet the engineer’s specification.

Working on a restricted residential site required close coordination to manage deliveries, crane operations, and the movement of materials while maintaining safe access. The complexity of the frame geometry, with its stiffened members and multiple connection types, demanded precise fabrication and careful handling on site to ensure the frame was plumb, level, and ready to receive follow-on works.

The project was completed to programme, with the frame handed over fully primed and ready for floor decking, roofing, and superstructure works to commence immediately. The result was an accurately installed structural frame that met all technical and dimensional requirements and provided a solid foundation for the remainder of the construction programme.

22 tonnes of steel, erected in just days — keeping the project perfectly on schedule.

MALFORD GROVE, SOUTH WOODFORDD

This project involved delivering a complete structural steel package to support the transformation of an existing property at Malford Grove, E18, into a modern and functional commercial space. The brief required a full site survey, design of connection details, production of fabrication drawings, supply of structural steel, and complete on-site installation.

Following the site survey, our design team produced connection details for approval by the project’s structural engineer and prepared fabrication drawings to coordinate with the builder’s programme. The package included multiple UC and UB sections, cranked frames, tie beams, columns, and bearing plates, all fabricated with precision and primed off-site.

The installation phase was carefully planned to suit the constraints of a residential street. Steels were delivered to site in phased loads, and a crane was used to lift members safely into position. Our installation team fixed the frame back to the existing structure, chem-fixed the baseplates, and ensured all components were plumb, level, and fully aligned before final tightening.

This project demonstrates our ability to coordinate survey, design, fabrication, and installation as a seamless package, ensuring a smooth programme for the client and enabling follow-on trades to begin without delay.

Our client, The Dental Build & Design by Laith, works exclusively with dental professionals to create bespoke, regulation-compliant clinics that are as functional as they are beautiful. Partnering with such a niche expert allows us to deliver steelwork packages perfectly tailored for clinical environments — helping dentists open their dream practices with confidence.

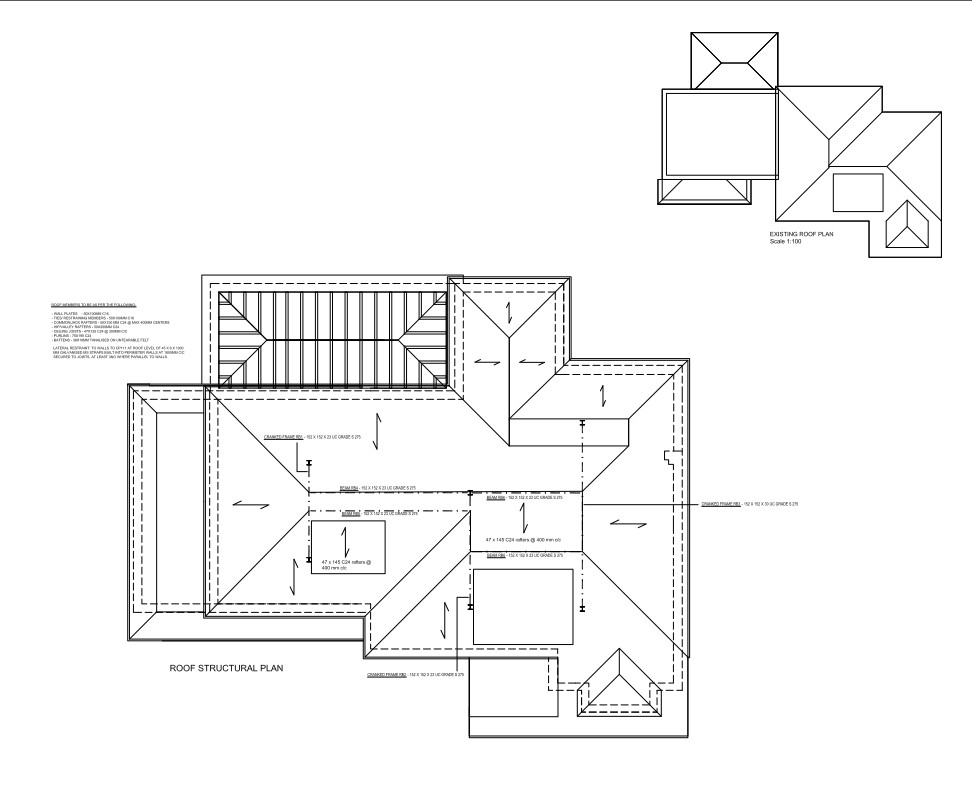

FINCHERS, BEAMOND END, AMERSHAM

Our team delivered the structural steel package for a substantial rear extension at a in Amersham. The project required precision fabrication and installation of multiple steel members, including UC and UB sections, crank frames, tie beams, bearing plates, and spliced connections.

Following a detailed site survey, we fabricated all components to the engineer’s specifications, including end plates, base plates, stiffeners, and splices for the 203 x 133 UB beams. The package featured a mix of heavy and light members, with the heaviest section being a 305 x 165 UB 54 complete with a 350 x 10 mm top plate to support new floor loads.

Installation required careful sequencing due to the number of crank frames and tie beams, which had to be precisely aligned to accommodate the roof geometry. Our team worked closely with the site contractor to ensure temporary works stability during the installation phase and to maintain programme deadlines.

The finished frame provided a robust and level structure ready to receive floor slabs and roof timbers. By coordinating fabrication, transport, and on-site erection, we ensured the client could progress straight to follow-on trades without delay, reducing the overall build programme.

This project featured five precision crank frames that had to be installed in exact sequence to match the complex roof design.

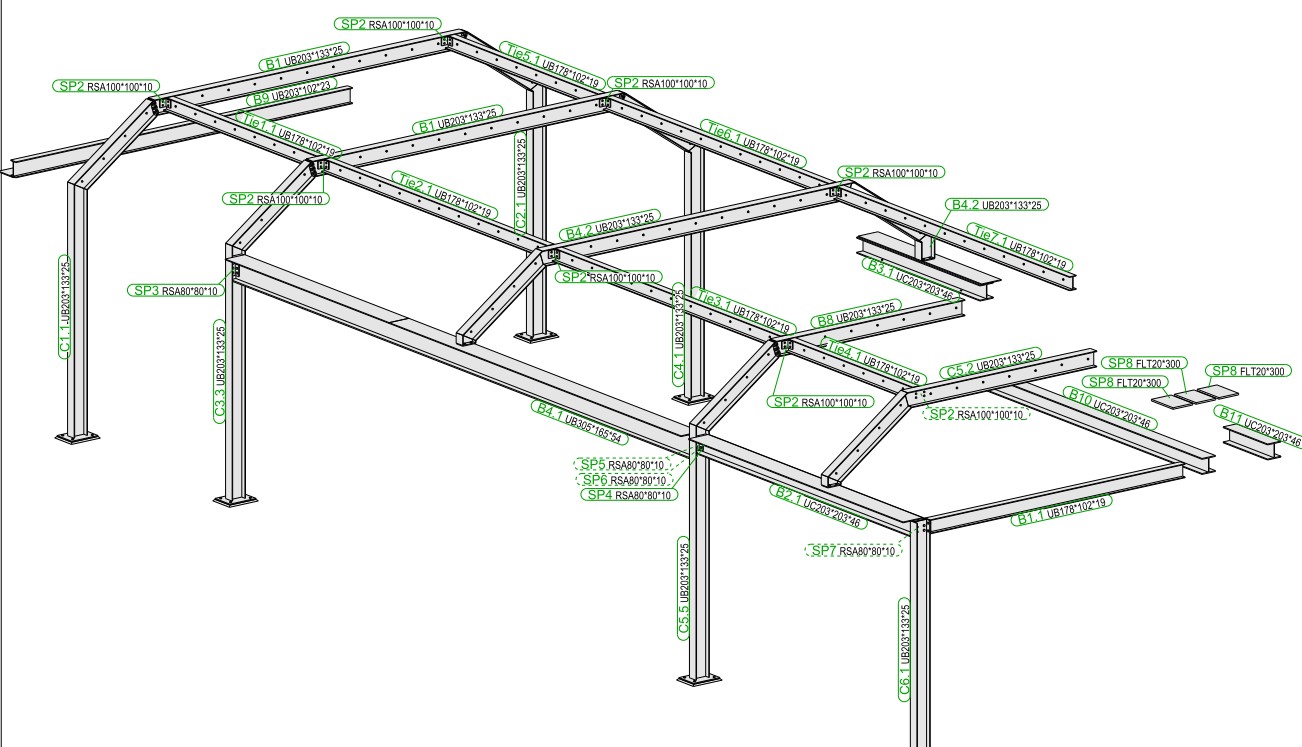

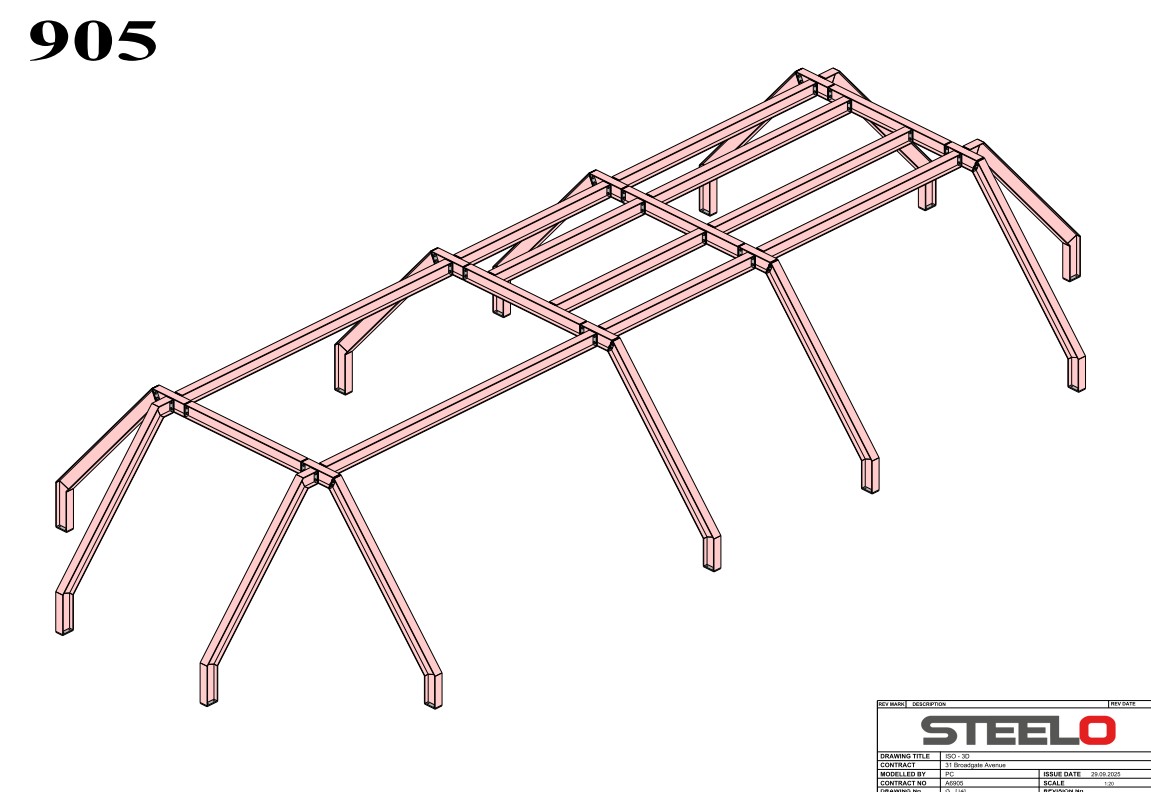

BROADGATES AVENUE, BARNET

This project delivered a highly detailed steel frame for a complex loft conversion and roof restructure. The package included UC and UB sections of varying spans, multiple kinked rafters with moment connections, spliced beams, stub posts, and SHS columns – all designed to create a strong and open internal space.

Our team carried out a detailed site survey before fabricating every member with precision, including end plates, base plates, flats, and splices to match the engineer’s design. Installation was carried out under full scaffolding and temporary works, with careful sequencing to keep the frame level and true.

The result is a robust and perfectly aligned steel frame, primed and ready for floor joists and roof timbers, allowing the project to move straight to follow-on trades.

Our client, Rustic Tiles, not only commissioned this steelwork project but also produces stunning brick tiles made from 19th-century bricks. Through double washing and polishing, they reveal the natural colours and textures of each piece. Their unique porosity creates a beautiful 3D wall effect — check out their website to see their full range!

WOODGATE CRESCENT, LONDON

This project involved the design, fabrication, and supply of a complex structural steel package for a large residential extension. The work was carried out for an occupied property with restricted access and a tight construction programme.

The scope included a detailed review of the architect’s and engineer’s drawings, followed by the preparation of fabrication drawings and connection details for approval. Once approved, our team fabricated over 5.58 tonnes of structural steelwork, including UC beams, stub columns, cranked beams, kinked angles, and associated plates. All items were precision cut, drilled, welded, and fully primed for corrosion protection.

The completed steel package was scheduled and delivered to site in line with the contractor’s programme, ensuring the materials were ready for installation as soon as the builder required them.

In total, more than 100 hours of workshop time were dedicated to producing the package. The result was an accurately fabricated, fully primed steel frame delivered on time and in full, allowing the contractor to proceed with installation without delay and keeping the build on schedule.

“For almost 10 years Steelo has been supplying beams for my projects. From single beams to entire roof structures or entire floor structures. They are always there to help and deliver beams on time.”

Cezary Tworek

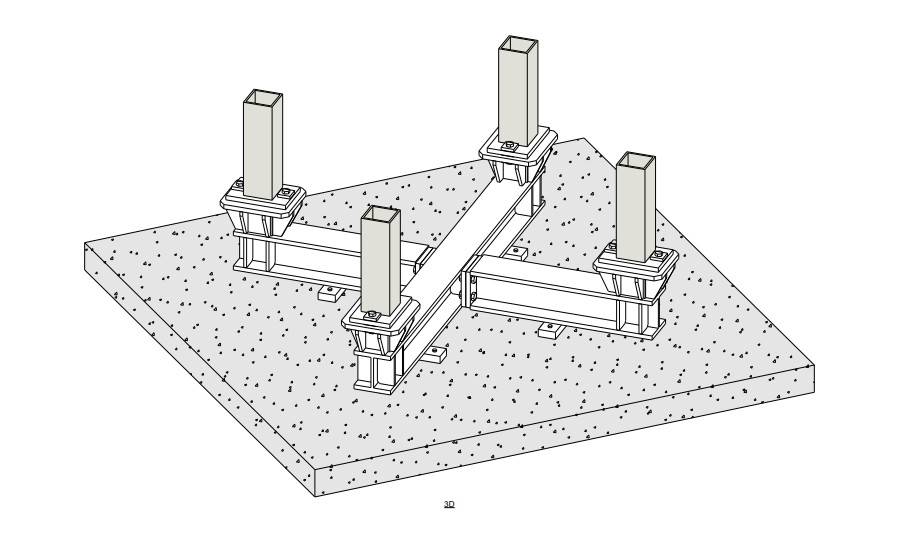

KINGSWAY BUSINESS PARK, ROCHDALE

For this project, Studio Construction Ltd. entrusted Steelo with the fabrication and supply of reinforcement steel to support the construction of a circular concrete foundation for a vertical LNG (Liquefied Natural Gas) storage tank. This formed a critical infrastructure component for Vigo Bioenergy Ltd’s expansion at Kingsway Business Park.

Unlike standard foundations, this installation demanded high-precision reinforcement to withstand extreme loading conditions and exposure to aggressive environmental factors — including chemical resistance, temperature fluctuations, and long-term durability.

What made this project stand out was the strict design specification for a perfectly circular rebar layout, engineered to support the VT 70/11 LNG tank. To achieve this, Steelo produced 62 custom-fabricated components in 12 mm and 16 mm diameters. Each bar was cut, bent, and clearly labelled according to a reinforced slab layout that included upper and lower rebar meshes, custom bar spacing, and a Hilti HIT-HY 200 anchoring system.

One of the key challenges was maintaining precise concrete cover tolerances and ensuring the reinforcement was prepared for rapid, error-free installation, as the on-site casting schedule allowed no delays.

The fabrication process involved over 100 hours of production, totaling 2.61 tonnes of steel.

All components were prepared for collection by external transport. Although delivery to Rochdale was outside our standard delivery scope, Steelo is always happy to accommodate clients across the UK with the aid of reliable external transport options.

The vertical LNG (Liquefied Natural Gas) storage tank is a highly specialized structure designed to safely contain natural gas at extremely low temperatures (around –162°C). These tanks are engineered for high-pressure containment, thermal insulation, and long-term durability, typically featuring a double-wall design with insulation layers between the inner cryogenic tank and the external shell. In this project, the VT 70/11 model required a reinforced concrete foundation capable of supporting significant vertical loads while withstanding environmental stress. LNG storage systems play a crucial role in energy infrastructure, enabling the transportation and storage of gas in liquid form for industrial and commercial use.