- The UK Research Consortium ‘HPWAAM’, funded by Innovate UK, the UK’s Innovation Agency (grant number 53610) and led by Weir Group, has exceeded key research milestones, accelerating additive manufacturing technologies beyond previous levels in terms of deposition rates and scale

- Productivity and efficiency performance achieved will help accelerate the adoption of additive manufacturing in high volume steel industries such as construction and mining

- The collaborative project between Weir Group, BOC, a Linde company, WAAM3D, Foster + Partners, Steelo, Wintwire and Cranfield University is on track to deliver its objectives by the end of 2023

UK – A business-led, commercially focused consortium, known as the High Productivity Wire Arc Additive Manufacturing (HPWAAM) group, has announced it has successfully demonstrated significant advances in technical capability which will enable additive manufacturing to play a greater role in the future of industry. HPWAAM embarked on the pioneering research in November 2020, and so far, it has exceeded key interim project objectives, notably:

- Increasing steel deposition rates to 15 kg/h, from a baseline of 3 kg/h, using a novel Wire Arc Additive Manufacturing (WAAM) process

- Applying new adaptive toolpath programming for different layer heights, unlocking potential for greater scales and complexities

- Successfully demonstrating the manufacturing of a 150kg part using high-deposition rate and in-process cryogenic cooling

The reported progress means that the consortium can now seek to industrialise HPWAAM for large-scale engineering components, featuring full thermal control and variable resolution. The project is scheduled to complete by the end of 2023, and brings together seven specialist organisations who are backed by £1.2m of funding from Innovate UK, which drives productivity and economic growth by supporting businesses to develop and realise the potential of new ideas. The collaboration builds on seminal research carried out by Cranfield University to develop a novel solution for a UK industrial sector, and already several strong commercial opportunities are being explored with end users. The development of this technology presents substantial potential improvements in terms of sustainability; such as reducing greenhouse gas emissions compared to traditionally energy intensive manufacturing processes, such as machining and casting. Looking ahead, the project’s end-users will create updated Design for Additive Manufacturing frameworks that will transform a series of existing commercial components in the latter phase of the HPWAAM programme.

Alan Stewart, Weir Group Head of Innovation and Research, commented: “Accelerating the Research & Development of new technologies is key to making mining more sustainable. Partnerships such as HPWAAM offer us a significant opportunity to harness the distinct strengths of domain experts spanning academia and adjacent industries, and in this case we are pushing the boundaries of wire arc additive manufacturing together. It is clear from the progress to date that this consortium is able to meet the objectives for productivity, and in simple terms, developing this capability means that in the near future we will be able offer customers new additive manufacturing solutions that can significantly reduce engineering lead times, create less material waste, improve equipment performance, and use less energy in the production process.”

Filomeno Martina, CEO of WAAM3D and spokesperson for the consortium, said: “The HPWAAAM Group achieving these milestones reflects the hard work, technical ability, and innovative ethos from the consortium partners. In the next phase we will leverage the combined capabilities of our partners towards developing an economically feasible way of printing large scale and complex designs at entirely new speeds. We are grateful for the critical funding provided by Innovate UK to pursue our ambition to create future value for our partners and wider UK industrial and commercial interests.”

ENDS

Contact:

WAAM3D Press Office

Background: About Additive Manufacturing

Additive Manufacturing (AM) technologies build objects directly from 3D model data, layer upon layer. Powder-based process variants are better suited for small but complicated objects, and leverage on their freedom of design to produce highly optimised components. Wire-based methods, however, are capable of producing much larger objects. The seminal work carried out by UK-based Cranfield University, started as far back as the mid-2000s. The findings have demonstrated that Wire Arc Additive Manufacturing (WAAM) can deliver considerably shorter lead times and reduce material waste compared to other traditionally established processes, such as subtractive manufacturing, casting or fabrication.

Today, additive manufacturing has been adopted by a large number of healthcare and aerospace companies but is a very small part of the metals industry. It is however growing rapidly and is expected to be worth as much as £60bn in 2030[1]. The HPWAAM project, which started in November 2020 and has received £1.2m of funding from Innovate UK, will take the WAAM process to the next level of industrialisation. The main objective is to increase the productivity of the WAAM process, to reduce part building time and costs further. Moreover, build strategies and approaches will be improved to achieve a higher level of resolution in the WAAM components, without compromising integrity and productivity. Together with fundamental process development, both these goals will require hardware and software innovation, especially in the fields of sensing, power delivery, and data preparation intelligence. Such new tools will be used to demonstrate the capabilities of HPWAAM for production of massive components, applicable to a large number of industry sectors, including mining, energy, and construction.

About the HPWAAM Consortium and Partner Roles

This business led, commercially focused project requires a broad consortium to deliver its ambitious targets and to create an industry-focused ecosystem for the wide-spread adoption of AM in large scale applications.

- BOC is the UK and Ireland’s largest provider of industrial gases and will lead the process development for global thermal control using cryogenic cooling and the development of a cryogenic cooling equipment package. boconline.co.uk

- Cranfield University, a wholly postgraduate university based in Bedfordshire, has 15 years’ experience of research into WAAM, and is leading HPWAAM process and equipment development, as well as supporting demonstrator parts building. www.cranfield.ac.uk

- Foster + Partners, an award-winning British international architectural design and engineering studio featuring innovative design and research in construction, is leading the HPWAAM process and system specification phase, providing optimised designs for construction applications and evaluating them. www.fosterandpartners.com

- Steelo, an innovative SME, is a lean manufacturer of construction systems. Using their existing WAAM system, they are investigating lattice structures and evaluating HPWAAM for construction applications. steelo.co.uk

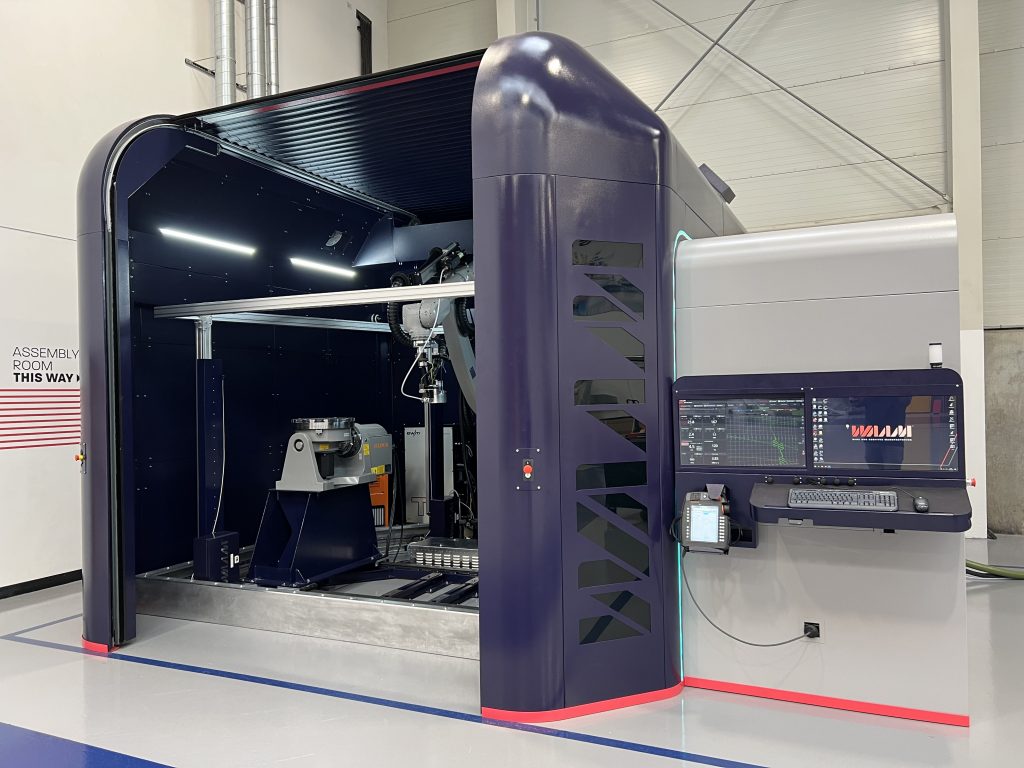

- WAAM3D is an SME that was originally a spin out from Cranfield University, and is providing WAAM systems, software and services. Recognised as the state-of-the-art, WAAM3D has won several awards including the 2022 TCT Award for Best Hardware in the non-polymer category for their RoboWAAM system. WAAM3D will upgrade their software for adaptable resolution and integrate the new HPWAAM process knowledge into their intelligent parameters calculation packages, which provide process information during the data preparation. WAAM3D is leading the project exploitation, also taking HPWAAM to other industry sectors.waam3d.com

- Weir Group, a global mining equipment leader, is project coordinator, and are leading the work of design of HPWAAM products, HPWAAM system evaluation though demonstrator building and evaluation. www.global.weir

- Finally, Wintwire, a specialist SME wire manufacturer, is providing high quality shaped wires needed for HPWAAM. Wintwire will supply novel wires for HPWAAM process studies and demonstrator manufacturing. www.wintwire.co.uk

The consortium will also assess the suitability of the WAAM process to repair and remanufacture large metallic components, as well as the impact of shorter supply chains enabled by the WAAM process. Indeed, a much more local approach to manufacture is now envisaged, with WAAM systems available on construction sites, oil rigs, or alongside mining sites. Such a paradigm shift is posed to reduce the environmental footprint of metallic part production, as well as mitigating the effect of the inherently lengthy transportation legs associated with traditional manufacturing approaches.

[1] https://www.researchandmarkets.com/reports/5595864/additive-manufacturing-market-size-share-and

Categories

Archives

- April 2024 (5)

- March 2024 (2)

- February 2024 (1)

- January 2024 (3)

- December 2023 (2)

- November 2023 (1)

- September 2023 (4)

- August 2023 (3)

- July 2023 (1)

- June 2023 (7)

- May 2023 (2)

- April 2023 (14)

- March 2023 (15)

- February 2023 (7)

- January 2023 (6)

- December 2022 (5)

- November 2022 (1)

- October 2022 (4)

- September 2022 (3)

- August 2022 (1)

- July 2022 (2)

- June 2022 (2)

- April 2022 (4)

- March 2022 (1)

- February 2022 (1)

- December 2021 (3)

- March 2021 (2)

- October 2020 (1)

- September 2020 (1)

- July 2020 (1)

- June 2020 (1)

- May 2020 (2)

- April 2020 (2)

- March 2020 (3)

- February 2020 (2)

- January 2020 (1)

- December 2019 (2)

- November 2019 (1)

- October 2019 (1)

- September 2019 (3)

- August 2019 (1)

- July 2019 (4)

- June 2019 (4)

- May 2019 (1)

- April 2019 (4)

- March 2019 (2)

- February 2019 (4)

- January 2019 (4)

- December 2018 (4)

- November 2018 (4)

- October 2018 (5)

- September 2018 (6)